ACTIVATION OF SLAG BLENDED CEMENTS BY AMINES

Cements containing blast furnace slags such as CEM III cements are increasingly used in both precast and ready-mixed concrete to improve the environmental footprint. However, the replacement of clinker by slag at a content varying between 35 and 95 wt% leads to a significant slow-down of cement hydration and consequently to a loss of early age strength. The use of activators containing amines can help to compensate this performance loss.

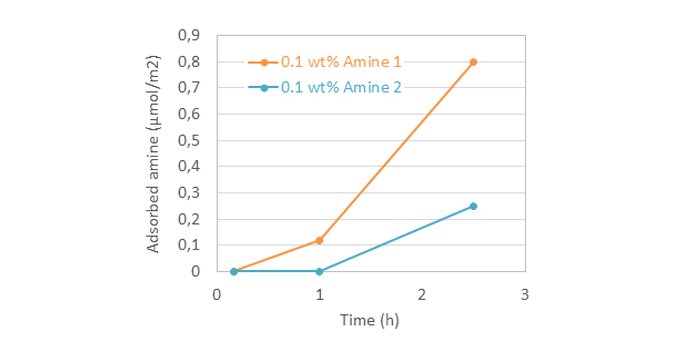

During this study, Amine 1 and Amine 2 were incorporated in a cement blended with 40 wt% slag at a dosage of 0.1 wt% in dry active matter. The quantity of amine adsorbed per blended cement specific surface was measured at 10 minutes, 1 and 2.5 hours of hydration. According to Figure 1, Amine 1 starts to adsorb on cement surface after 1 hour of hydration and the phenomenon continues at 2.5 hours with a significant increase of the adsorbed amine quantity. On the other hand, Amine 2 adsorption only starts at 2.5 hours and in a smaller quantity compared to Amine 1. Thus, depending on the nature of the amine, the occurrence time of adsorption and the quantity of amine adsorbed will be different, which might have an impact on cement reactivity.

Figure 1 : Quantity of amine adsorbed in a cement blended with 40 wt% slag at different hydration times in presence of Amine 1 and Amine 2[1]

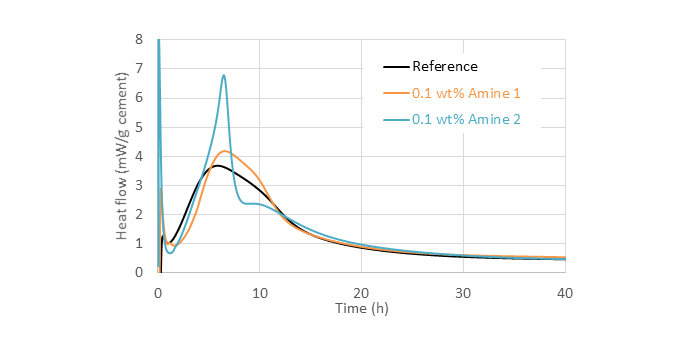

Regarding the hydration kinetics, the addition of 0.1 wt% Amine 1 and Amine 2 inside the slag blended cement significantly modifies the heat flow evolution (Figure 2). Amine 1 leads to a lengthening of the induction period, but also an increase of the main peak intensity. On the other hand, Amine 2 strongly modifies the shape of the main hydration peak with an intensity increase. Both amines act as activators for the hydration of the slag blended cement.

Figure 2 : (a) Heat flow evolution of a cement blended with 40 wt% slag in presence of Amine 1 and Amine 2 [1]

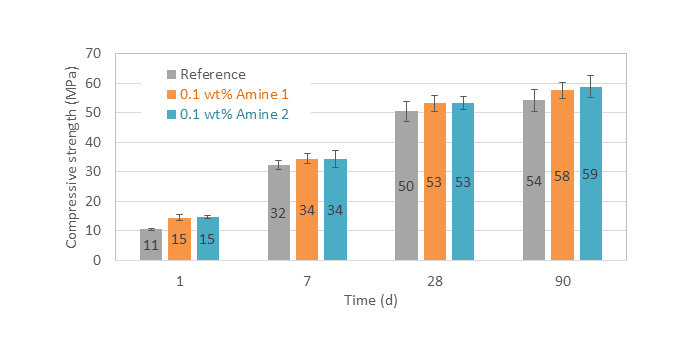

Finally, an increase of compressive strength is measured at 1 day with Amine 1 and Amine 2 compared to the reference (Figure 3). This gain in mechanical performance confirms the activator impact of the amines already observed by following hydration kinetics. Using an amine can thus allow to compensate the loss of mechanical strength observed during substitution of clinker by slag. Moreover, the presence of the amines allows to maintain slightly higher compressive strength values for the slag blended cement up to 90 days of hydration. This knowledge about amines allowed the R&D teams at CHRYSO to develop tailor-made additives for slag blended cements, leading to the CHRYSO®AMA 100 EL Technology.

Figure 3 : Compressive strength of a cement blended with 40 wt% fly ash without and with 0.1 wt% TEA [1]

Marie JACHIET – PhD in Chemistry and Physico-Chemistry of Materials

References

- Rachel REIVER, Study of the main modes of action of accelerator molecules on blended cements, PhD thesis, IMT Mines Alès, 2021