LUMINTECH®, COLOURED PHOTOLUMINESCENT PARTICLES FOR DECORATIVE CONCRETE

The introduction of luminescent pigments in materials in order to provide visibility in low light or zero brightness (night, shade, darkness, interior unlit due to an electric failure…) is sought.

There are different types of luminescence depending on the excitement: bioluminescence with enzymatic excitation, thermoluminescence with thermal action…

Photoluminescent particles have the property of absorbing UV radiation (natural or artificial) and then subsequently releasing this energy in the form of visible light without any thermal phenomenon. From the physical point of view, the material is an optical effect semiconductor with a charge-discharge property (by analogy with a conventional battery). The absorption-emission cycle occurs without wear or aging of the material. It can therefore be reproduced indefinitely. Energy absorption with the movement of electrons to excited levels and then release of this energy in the form of photons when the electrons return to their ground state.

LuminTech® innovation provides good visibility over a long period, typically over several hours. This is of particular interest for applications of the signaling type, extra lighting, improvement of the aesthetic of a material, for example graphic, visualization, decoration…

These particles have the property of absorbing UV light (natural and artificial) during the day, and emit some visible light in a dark and low light environnement. The day colours imitate perfectly natural aggregates, while the night colours reveal luminescent different colours.

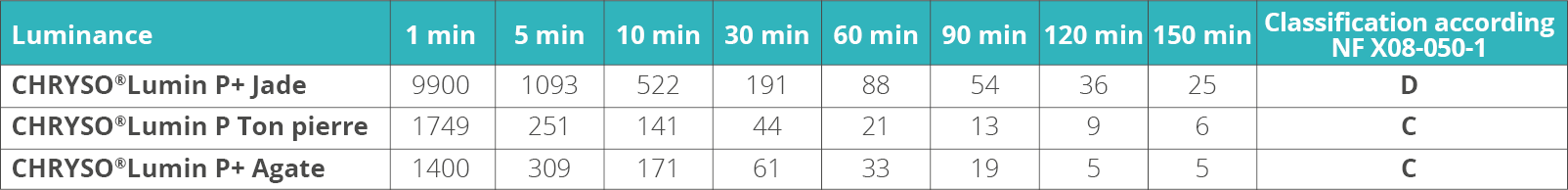

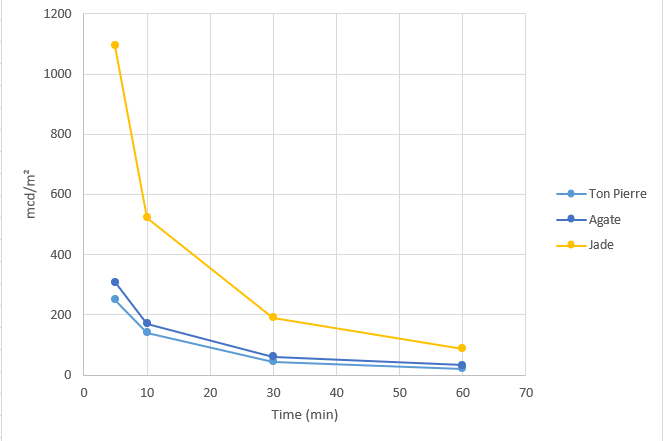

The luminance assessment is carried out according to NF X 08-050-1 + DIN 67510-1. The purpose of the test is to measure the light intensity (in mcd/m2) emitted at the particle’s surface after 5 mn of exposure to a 1 000 lux lamp type D65 (similar to sunlight irradiation spectrum).

Figure 1 : Light emission (luminance) values emitted by the samples according NF X 08-050-1

With their luminance at 10 min and 60 min (measured according to NF X 08-050-1), LuminTech® particles can be qualified in category C and D, ie the most photoluminescent.

For all the samples, the emission intensity is lasting over 10 hours above the visibility threshold value of à 0,3 mcd/m2, human eye detection limit.

These aggregates were characterized according to the test carried out on the “conventional” aggregates.

- Abrasiveness and grindability according NF P 18-579

- Los Angeles test according EN 1097-2 to evaluate the resistance to fragmentation induced by shocks

- Microdeval test according EN 1097-1, to evaluate the resistance to wear by mutuel friction.

The values show a low abrasiveness, a good resistance to grinding, and an high resistance to fragmentation by shock and to wearing by mutual friction.

The particles’s main component is a highly durable recycled polymer. The luminescent pigment is a photoluminescent compound capable of absorbing photons emitted by natural or artifical light. The pigment (for the diary colour) is a mineral pigment because of its greater durability.

CHRYSO®Lumin P particles imitates real aggregate colors during the day and show a completely different color in the dark

The properties of CHRYSO®Lumin P allow its particles to be easily used in decorative concrete.

Sandrine MATEO – Aesthetic Research Team Leader

References

FR 3041651, Colored luminescent pigment, process for preparing the same and uses thereof, HIVERT JJ, CHRYSO, 2015